TL;DR — Galinstan (Ga-In-Sn) is a room-temperature liquid metal with a big coefficient of thermal expansion and excellent thermal conductivity. Heat it and it expands—hard—which you can convert into precise hydraulic force. That unlocks actuators and flow control that keep working at temperatures where ordinary fluids fail. We outline designs for spacecraft thermal control, adaptive aero surfaces, high-temp industrial valves, engine cooling, and solar trackers—plus the engineering gotchas (compatibility, sealing, pressure relief) and a test plan.

Why Galinstan?

Most hydraulic fluids hate heat: they break down, outgas, or change viscosity. Galinstan (≈ 68.5% Ga, 21.5% In, 10% Sn) stays liquid from about −19 °C up to extremely high temperatures, conducts heat well, and expands significantly with temperature. That gives you a neat trick:

Heat → volumetric expansion → pressure rise → motion/force

(Cool it and you get the reverse.)

Because the input is simply temperature, you can drive actuators with waste heat, resistive heaters, or environmental cycles—no pumps required.

The core mechanism (in one minute)

-

Reservoir + Expansion Chamber — A temperature-controlled reservoir feeds a sealed chamber.

-

Thermal Input — Heaters or waste-heat sources nudge Galinstan temperature by ΔT.

-

ΔT → ΔV — Thermal expansion increases fluid volume/pressure.

-

Work Output — Pressure moves a piston/diaphragm → actuator stroke, valve shift, or flow control.

-

Control — PID over temperature (and pressure relief for safety) gives repeatable positioning/force.

Where this shines

1) Spacecraft thermal control

Use Galinstan’s expansion to throttle heat pipes, open/close louvers, or bias radiators—no complex pumps. Precision comes from tight temperature control; reliability from no moving pump parts.

2) Adaptive aerospace structures

Variable-geometry tabs/flaps actuated by ΔT. Real-time trim without traditional hydraulics, leveraging onboard electrical power or skin-temperature differentials.

3) High-temp industrial actuators

Furnaces, reactors, foundries: actuate valves/dampers where oils cook off. Non-flammable, stable, and thermally responsive.

4) Engine cooling & thermal management

Dynamic bypass/valving driven by block/head temperature. High conductivity helps scavenge hotspots; no cavitation issues typical of boiling liquids.

5) Solar tracking (CSP/PV)

Day-night or controlled ΔT expands Galinstan to index mirrors/panels for optimal angle, cutting mechanical complexity.

Engineering checklist (what can bite you & how to mitigate)

-

Material compatibility

Galinstan can attack aluminum and wet certain metals aggressively. Prefer 316/304 stainless, Ni-based alloys, selected polymers/ceramics. Add inert coatings on wetted parts where needed. -

Wetting & oxide skin

Gallium oxides can form skins that alter flow. Design with smooth passages, consider inert gas headspace, and keep oxygen ingress low. -

Seals & embrittlement

Use gallium-resistant elastomers or metal bellows; validate long-term exposure. Avoid Cu/Al where intermetallics are a risk. -

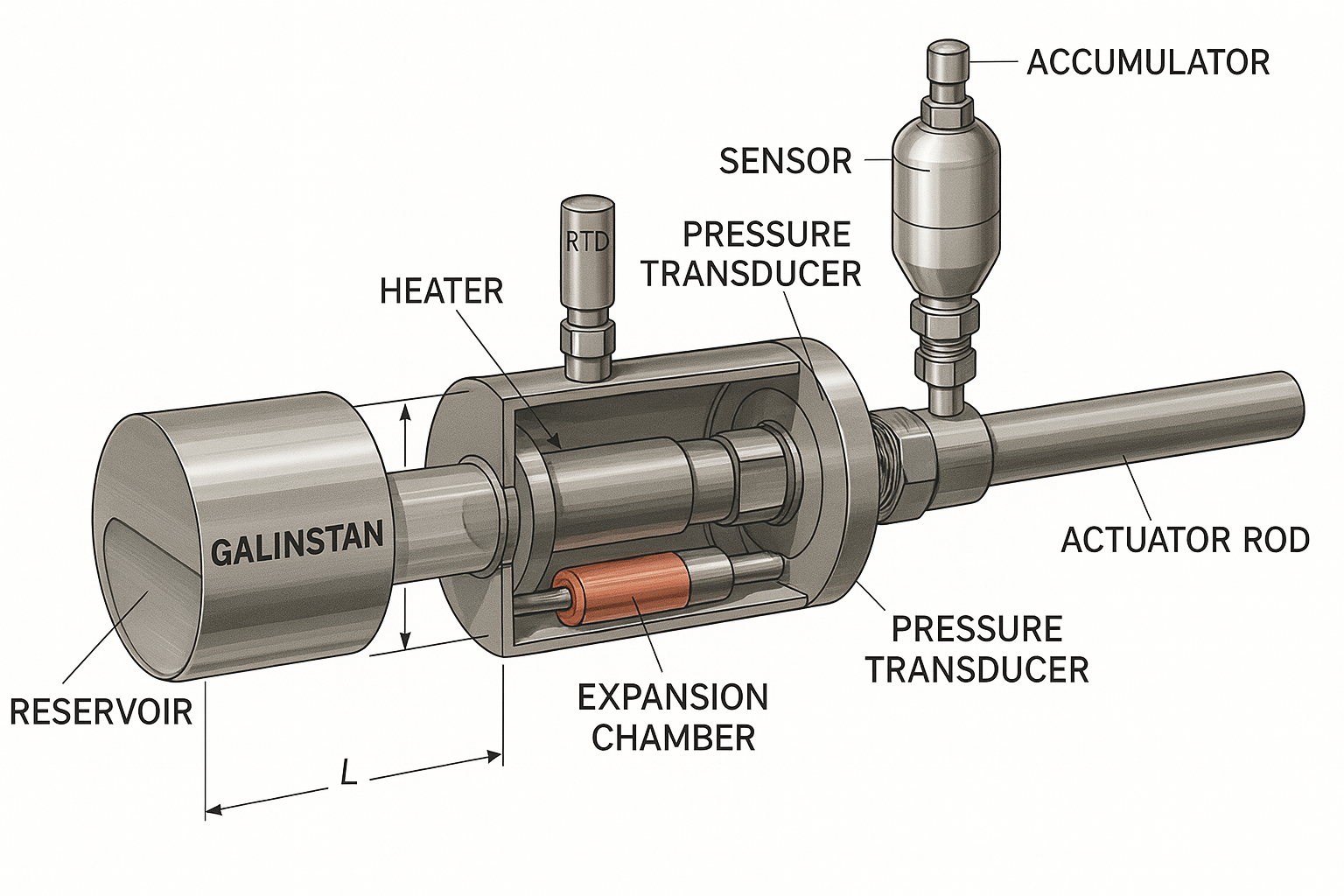

Pressure relief & compliance

Thermal expansion can spike pressure quickly. Include relief valves, accumulators, and temperature-rate limits. -

Control loops

Temperature is your “throttle.” Add fast thermal sensors, well-placed heaters, and insulation. PID is usually sufficient; model the chamber’s thermal mass. -

Safety & handling

Galinstan is non-toxic (vs. mercury) but still a spill risk; build in containment and service procedures.

Minimal viable test plan (bench → field)

Bench rig:

-

50–250 ml sealed expansion chamber (316L), cartridge heater, RTD/thermocouple, pressure transducer, relief valve, stroke-measuring actuator.

-

Cycle ΔT in small steps (e.g., 5–10 °C) and map ΔT → ΔP → stroke/force.

-

Characterize hysteresis, response time, and power draw.

KPIs:

-

Force/stroke per ΔT

-

Repeatability over 10k–100k cycles

-

Leakage rate (mass balance)

-

Material/Seal degradation (post-mortem inspection)

Scale-up:

-

Integrate with representative thermal sources (engine head, furnace wall, radiator panel).

-

Environmental tests (vibration, shock, vacuum where applicable).

Where it probably doesn’t fit

-

Ultra-fast, high-bandwidth actuators (ms-level response): thermal time constants are the limit.

-

Aluminum-heavy systems where redesign/coatings aren’t feasible.

-

Applications intolerant to any liquid metal exposure (special contamination regimes).

What makes this interesting

It turns heat—often waste heat—into precise mechanical work with no pumps, few moving parts, and survivability at temperatures that ruin conventional fluids. It’s a clean example of mechanism-anchored engineering: define the primitives (thermal expansion, conductivity, compatibility), constrain the edge cases, and give teams a testable path.